Six-wheel-drive vehicles are develop for environments where traction, stability, and load security must maintain over long distances and unpredictable ground.

Soft sand, deep mud, fractured rock, and extend gradients place demands beyond the capability envelope of conventional drivetrains.

The Toyota HyperMax 6×6 framed as Toyota’s conceptual response to those conditions, focusing on control movement, structural resilience, and dependable operation in locations where recovery options and infrastructure are limited.

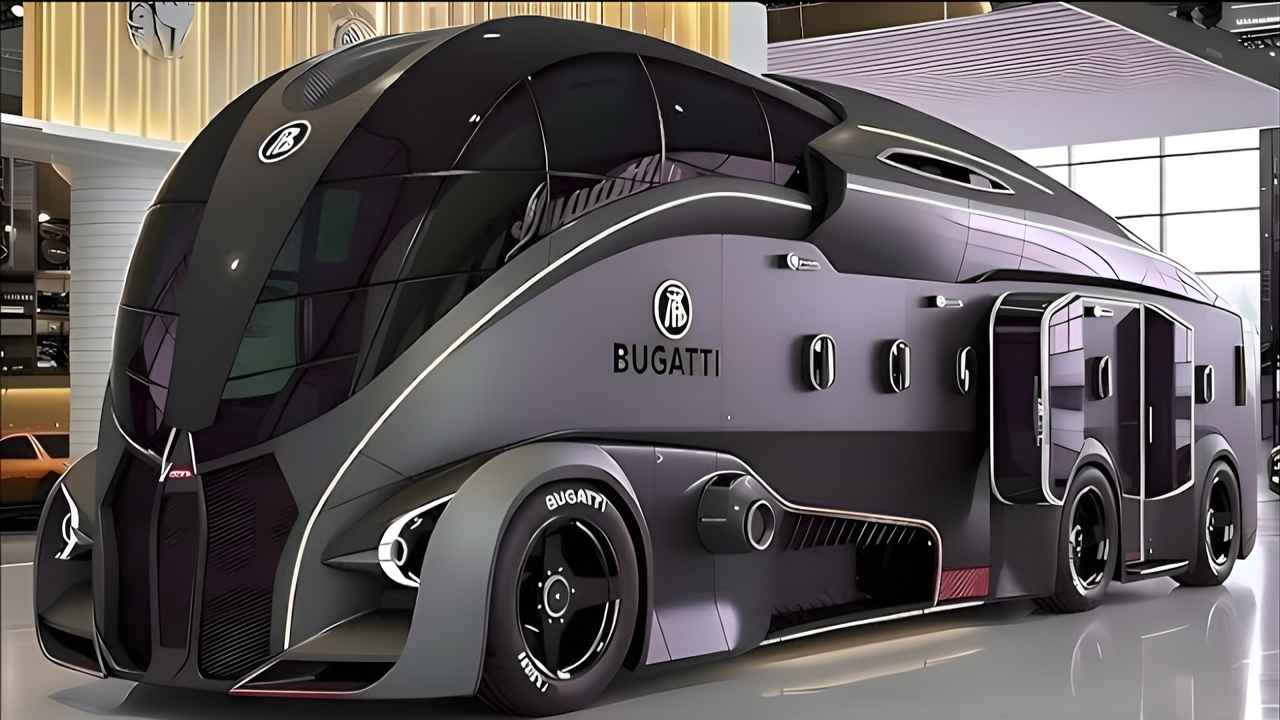

2026 Toyota HyperMax 6×6

The 2026 Toyota HyperMax 6×6 framed as a purpose-built extreme-duty vehicle, develop for harsh terrain, heavy payloads, and long-distance off-grid operation, combining a reinforced six-wheel-drive layout with durability-led engineering rather than comfort or speed.

Current discussion around the HyperMax focuses on its permanent 6×6 drivetrain, triple locking differentials, heavy-duty suspension, and extended fuel range, positioning it as a low-volume specialist Toyota platform aimed at expedition, industrial, and remote-area use in 2026.

2026 Toyota HyperMax 6×6 Technical Review

| Vehicle name | Toyota HyperMax 6×6 |

| Model reference | 2026 (as used in concept material) |

| Vehicle class | Extreme-duty six-wheel-drive platform |

| Chassis concept | Reinforced Toyota ladder-frame architecture |

| Production status | Concept or specialist low-volume project |

| Seating concept | Multi-occupant layout suitable for long missions |

| Powertrain concept | Torque-focused combustion or hybrid approach (unconfirmed) |

| Transmission concept | Heavy-duty automatic transmission |

| Drivetrain layout | Permanent six-wheel drive |

| Differential strategy | Front, centre, and rear locking capability (conceptual) |

| Load intent | Engineered for sustained heavy payload use |

| Towing intent | Designed for demanding towing conditions |

| Efficiency focus | Endurance prioritised over consumption figures |

| Fuel strategy | Long-range layout with auxiliary storage implied |

| Proportions | Large-format, high-clearance expedition stance |

| Wheelbase layout | Extended configuration with dual rear axles |

| Tyres and wheels | Oversized off-road tyres on reinforced wheels |

| Braking concept | Heavy-duty braking system for high mass |

| Safety focus | Stability, traction, and passive protection systems |

| Price position | Specialist-tier positioning, not announced |

Note – Toyota has not release a formal specification sheet for the HyperMax 6×6. The table below reflects only non-numeric, publicly discussed conceptual attributes, without inferred performance data.

Role Definition: A Machine With a Mission

The HyperMax 6×6 is conceived as a working platform, not a recreational showpiece, with its purpose defined by function rather than lifestyle appeal. Primary mission profiles –

- Remote expedition and exploration transport.

- Specialist industrial and field-support operations.

- Long-duration, self-reliant off-grid travel.

- Civilian deployment inspired by military-grade design logic.

Backbone Engineering: The 6×6 Foundation

At its core, the HyperMax concept is built around a reinforced body-on-frame structure adapted to support three driven axles and prolonged structural loading.

Structural layout fundamentals –

- Heavy-duty ladder-frame construction with additional reinforcement.

- Triple-axle configuration for enhanced ground contact and stability.

- Rear-axle load-sharing geometry to control mass distribution.

- Conceptual front, centre, and rear driveline management.

Power Delivery Over Peak Performance

| Engineering priority | Design intent |

|---|---|

| Output philosophy | Emphasis on usable torque |

| Power character | Controlled delivery at low and mid speeds |

| Heat management | Enhanced cooling for sustained operation |

| Reliability target | Long service life under continuous load |

The HyperMax powertrain concept is shape around predictability and thermal stability, supporting extend operation under load rather than short bursts of performance.

Suspension Tuned For Weight & Terrain

The suspension design concept focuses on maintaining wheel contact and stability while managing significant mass over broken surfaces. Suspension development goals are –

- Heavy-duty long-travel suspension layout.

- Managed articulation for uneven terrain.

- Load-support systems for variable rear weight.

- Stability tuning for tall, fully equipped configurations.

Traction Systems For Controlled Progress

Mechanical hardware and electronic aids are conceptually integrated to support steady movement across difficult terrain.

- Traction and control features.

- Low-speed crawl assistance.

- Selectable terrain response modes.

- Full locking differential functionality.

- Hill ascent and controlled descent systems.

Exterior Shaped by Function, Not Fashion

The exterior of the HyperMax is defined by operational needs rather than styling trends, with protection and recovery prioritised.

- Functional exterior components

- Purpose-built body panels with reduced overhangs.

- Steel bumpers and comprehensive underbody shielding.

- Rated recovery points at both ends.

- High-output auxiliary lighting for remote environments.

Rear Platform Design to Work

Instead of a conventional pickup bed, the rear section is conceived as a modular working surface. Load deck characteristics are –

- Flatbed or modular rear platform configuration.

- Integrated mounting and securing points.

- Compatibility with expedition or equipment modules.

- Load distribution managed across rear axles.

Interior Built For Long Days, Not Luxury

Inside, the HyperMax concept prioritises clarity, durability, and endurance. Must look cabin design principles are –

- Upright, supportive seating for extended use

- Hard-wearing materials resistant to dirt and wear

- Large, glove-friendly physical controls

- Practical storage for tools and mission equipment

Technology That Serves the Driver

| System focus | Concept application |

|---|---|

| Navigation | Global and off-road mapping support |

| Visibility | Multi-angle camera views for terrain awareness |

| Communication | Provision for satellite and long-range systems |

| Interface design | Simple, task-oriented control layout |

Technology is intend to enhance situational awareness and navigation without adding unnecessary complexity in high-stress environments.

Safety Through Strength & Control

Safety engineering centres on structural integrity and controlled vehicle behaviour rather than high-speed scenarios.

- Passive Protection

- Reinforced occupant structure.

- Integrated airbag systems.

- Active Assistance

- Stability and traction management.

- Load-aware braking support.

- Structural Defence

- Strengthened frame sections.

- Underbody protection for critical systems.

Design to Go Far From Support

| Capability focus | Concept intent |

|---|---|

| Range objective | Extended operating range |

| Auxiliary support | Additional fuel and power storage options |

| Efficiency balance | Consumption traded for reliability |

The HyperMax is conceptually configured to operate well beyond established infrastructure, supporting extended missions without frequent resupply.

A Platform Meant to Be Adapted

The HyperMax 6×6 is design as a base for specialised builds rather than a fixed-format vehicle. Adaptation potential are

- Expedition and research vehicles.

- Industrial and remote-service conversions.

- Emergency and disaster-response platforms.

- Overland and self-contained camper builds.

Where It Sits in 6×6 World?

The HyperMax occupies a functional niche within the limited six-wheel-drive landscape.

| Vehicle | Core focus | Positioning |

|---|---|---|

| Mercedes-AMG G 63 6×6 | Luxury performance | Prestige-led |

| Hennessey VelociRaptor 6×6 | High-output off-road | Enthusiast-focused |

| Custom military-style 6×6 platforms | Utility and payload | Mission-driven |

The HyperMax differentiates itself by centring on sustained operational capability rather than visual impact or performance spectacle.

Production Outlook & Availability

At present, the HyperMax 6×6 remains a concept or specialist-level project. Toyota has not confirmed production scale, regional allocation, or a formal market launch timeline.

Capability Before Comfort

The Toyota HyperMax 6×6 is conceived for users who require dependable access in environments where conventional vehicles struggle to operate consistently and safely.

Its design direction places structural strength, durability, and operational endurance ahead of refinement or visual drama, reflecting a machine shaped by real-world demands rather than mainstream consumer expectations.